Six Functions of Machine Management

No two fleets are managed in exactly the same manner, but all successful operations include six key functions

Equipment management touches nearly every aspect of a company's operations. The skills required vary from the master mechanic to the finance specialist, and organization structures depend more on the personalities involved than on careful planning and forethought. Yet every company approaches the complex and difficult task of equipment management in its own way.

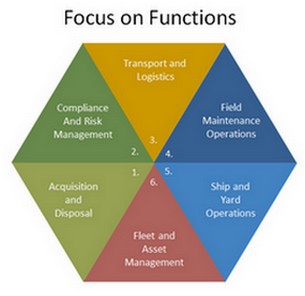

There are, however, six functions t hat must be competently performed, presented graphically in the diagram in the sidebar. An equipment-using organization should cover all these functions and ensure that everyone understands their responsibilities and contribution to the business. For each function, consider its importance, who is responsible, and how success is measured.

An effective equipment- management strategy must include these six functions. Everyone involved in the fleet must understand responsibilities, function and measurements of success.

- Acquisition and disposal. Effective acquisition and disposal is not just a question of buying low and selling high. Acquisition makes up a major portion of total owning cost and requires that long-term technical and commercial decisions are based on knowledge of the market and the relationships established with manufacturers and finance organizations. Managers need to develop specifications tailored to their needs; have policies on standardization; and know how to structure purchase, lease, rental-purchase or rental agreements suited to their financial and tax situation.

Disposal of equipment at the best possible price requires that managers understand the used-equipment market, explore every possible alternative, and maintain effective relationships with dealers and agents. - Compliance and Risk Management. This function makes up the second portion of total owning cost and covers the steps needed to ensure that fleet assets comply with all regulations and are licensed, insured and inspected as needed. On the surface, it appears to be a relatively simple, routine task. This task is, however, growing in cost and complexity as we see more emphasis on complex insurance requirements, emissions standards and safety regulations. This function becomes extremely complex when operations are performed in many states or in international markets. It simply cannot be neglected.

- Transport and Logistics. Acquisition and disposal ensure that we have the required equipment in our fleet; compliance and risk management ensure that it is legal. The transport and logistics function moves it to the right place at the right time.

Effective dispatch and tracking operations are essential for fleet utilization, and many companies run large transportation fleets that move equipment on a daily basis. Questions often arise as to whether the costs should be part of the equipment rate or be charged directly to the projects involved. Regardless, it is another cost that must be controlled, and another equipment-management function that must be competently performed. - Field Maintenance Operations. This function covers all the actions needed to make sure that the equipment on site is available and able to work on a daily basis. It includes fueling and daily inspections, periodic and preventive maintenance, and the replacement of wear parts. The costs involved form part of total operating cost and must be included in the equipment rate.

Questions arise when it comes to deciding who sets field-maintenance standards, who is responsible for differences between actual and budgeted costs, and who is responsible for field-maintenance mechanics. Clearly, small projects can't assume these responsibilities; clearly, large projects can and, perhaps, should. - Shop and Yard Operations. Changes in machine design, shortages of field personnel, and the need to work under controlled conditions means that very little repair, renovation or rebuild work is done in the field. Shop and yard operations, either self-performed or outsourced, lie at the heart of a process whereby machines come off field assignment and are made ready for their next job.

The costs involved make up the second component of total operating cost, and the success of this function determines the long-term capability and reliability of the equipment fleet. It is critical for the success of the company, and many aspects of shop and yard operations can benefit from the efficiency and specialization achieved through outsourcing. - Fleet and Asset Management. This function is responsible for strategic decisions regarding fleet composition, fleet average age, capital expenditure, finance, tax and return on investment. It absorbs data from the other functions; interfaces with the company strategic-planning process; and develops the rates, estimates, budgets, benchmarks and standards needed to manage the whole process.

A focus on this function can achieve substantial benefits in terms of capital structure, tax planning, cash management, and return on investment. Successful companies excel in this area and make strategic decisions that balance the technical, operational and financial aspects of managing the fleet as a major corporate asset.

Steps to organization

Using the six functions and their arrangement in the hexagon, we can draw some general conclusions regarding the way we organize our company to better manage the fleet.

The three functions in the top half of the hexagon (compliance and risk management, transport and logistics, and field maintenance operations) are short-term immediate issues of primary concern to the jobsite. They want equipment that is legal, in the right place, and working. Project teams can and, in many situations, should manage these functions within a framework of clear and strongly enforced policies.

The three functions in the bottom half of the hexagon (acquisition and disposal, shop and yard operations, and fleet and asset management) are long-term strategic issues of primary concern to the company and its long-term future. There is no doubt that these are the province of the equipment professional and should be managed for the long run. Competence in these functions is a corporate responsibility and a prerequisite for success in the upper three functions.

Functions 1 and 2 make up owning costs; functions 4 and 5 make up the operating cost. Each has a long-term "invest for the future" component (1 and 5), and each has a monthly or hourly cost component (2 and 4). Function 6 ensures that the fleet age, size and composition match corporate requirements; function 3 makes sure the fleet is deployed in the right place at the right time.

It should be possible to review each of the functions and assess its importance to your company. It should also be possible to identify the individuals or teams who have primary responsibility for each function and see whether they have the knowledge, guidance and authority needed to succeed.

Ready to Compare Maintenance Management Software Price Quotes?