Internal Combustion (IC) Forklifts

Internal combustion (IC) forklifts burn fuel in engines similar to automobile engines. They're the most common choice for outdoor use: electric forklifts can't be safely used in the rain. In addition, only IC forklifts are capable of handling the largest loads. If you require greater than 15,000 lbs capacity, you definitely need an internal combustion engine.

IC forklifts can run on gasoline, diesel fuel, liquid propane, or compressed natural gas (CNG). Operating costs are generally highest for gasoline and lowest for diesel, with propane and CNG somewhere in the middle. The choice is often made based on existing vehicles and equipment: if you already have diesel vehicles and fuel storage, it's best to go with diesel forklifts as well.

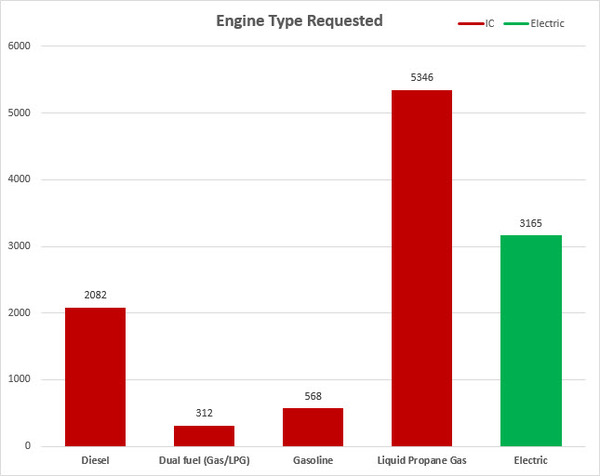

Forklift Engine Types Requested in 2014

So far in 2014, around 80% of individuals that have requested a forklift through BuyerZone requested one that with an internal combustion (IC) engine. Business owners have relied on these machines for a number of reasons over the years. One of the main advantages IC forklifts provide is the ability to be refueled on the fly. Simply fill it up at a gas pump or load a new propane canister on and your forklift is ready to continue working in no time. They are cheaper to buy than electric forklifts - 30% to 50% less in many cases - but cost more per hour to run. With the current national average of 10 cents per kilowatt/hour for charging batteries, most electric forklifts cost approximately 75 cents per hour. IC forklifts, taking into account national averages for LPG costs, will run about $2 per hour to operate.

IC forklifts also stand up to certain types of misuse better than electric lifts - specifically, using a forklift to push or tow loads, instead of lifting and driving - and usually have better acceleration and top speeds. In large outdoor work sites, this can be an advantage.

Maintenance: IC vs. electric motors

More power means more moving parts. And more moving parts means more things that can go wrong. Maintenance requirements for an IC forklift engine entail routine service and inspection for:

|

|

An electric motor will also require maintenance. But in contrast, there are far fewer parts that offer potential replacement. Electric service primarily looks for:

- Leaks around seal bearings

- Cooling fans - clear and providing adequate airflow

- Drive belts - seated correctly and don't show signs of wear

- Noise level

- Loose electrical terminals

- Adequate supply voltage

| Internal combustion forklift specifications | |

| Available capacity | 3,000 - 35,000 lbs. or more |

| Power source | Gasoline, diesel fuel, liquid propane gas, or compressed natural gas engine |

| Costs | Lower purchase price; Higher operating costs |

| Best used | Outdoors (Propane: Indoors or Outdoors) |

| Typical Applications | Distribution centers, construction, lumberyards |

| Refueling time | 5 to 15 minutes |